Testing and Commissioning Service

TESTLEADS ELECTRICAL SERVICES is testing and commissioning services provide the expertise to complete your project safely, per your plans and specifications, on time, and within budget. Proven testing and commissioning procedures is essential to the long-term reliability of an electrical system. Improper installation and commissioning can cause equipment failures. With TESTLEADS testing and commissioning services, you can be assured that your equipment has been tested and commissioned properly.

More than half of early equipment failures can be traced to design, installation, or testing deficiencies. Many avoidable outages are due to improper testing procedures, coordination and calibration of protective devices as well as wiring errors, design errors, etc.. In other cases, the failures don't occur until months after the equipment has gone into operation and the warranties have expired.

When improper testing and testing procedures are applied, the results can be devastating. Your electrical system could experience a catastrophic failure due to relatively small installation and testing errors. TESTLEADS’s Commissioning & Testing Services can verify that the equipment has been properly installed and its function complies with the purchase specifications and design.

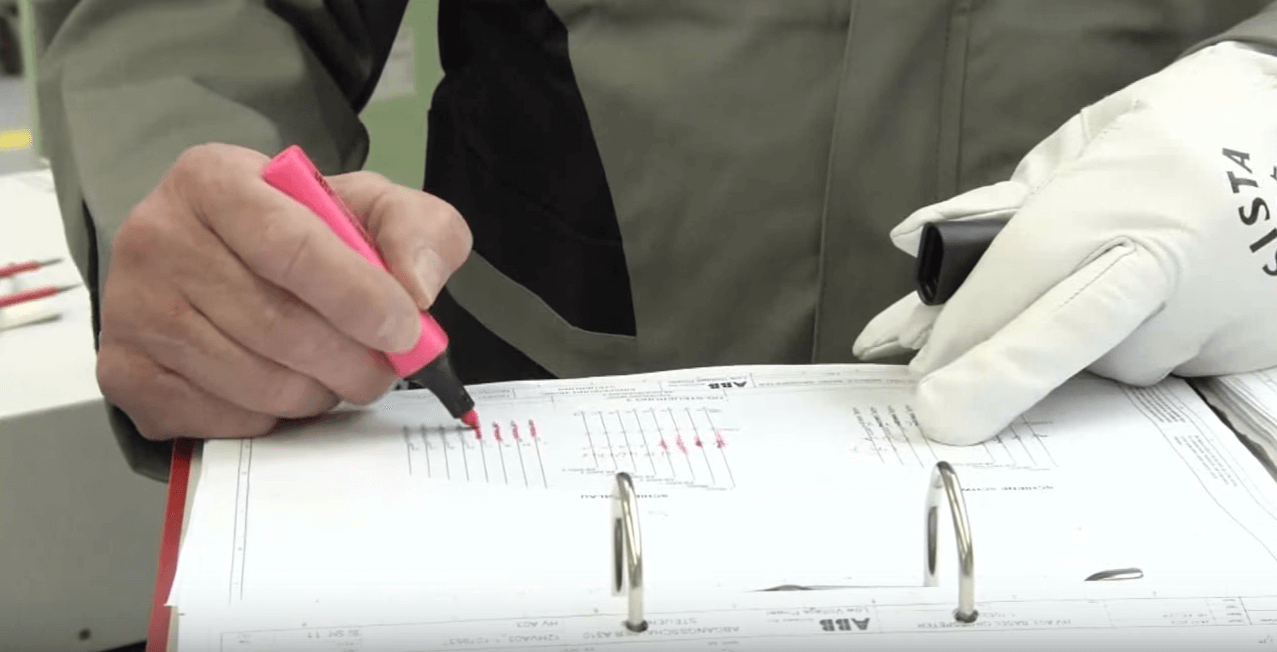

Design Review

TEST LEADS technical staff can conduct a design review of your electrical distribution system to identify areas to reduce potential hazards. Several areas are evaluated including fault levels, exposure times, remote operations, remote racking, and system grounding. Employing special devices and altering current design can significantly reduce fault levels, arcing time, arc incident energy, and arc blast force. Conducting a design review is the most effective way to uncover potential hazards so these types of solutions can be employed.

Single Line Diagrams

Requirements mandate accurate, up-to-date single-line diagrams. These documents are essential for documenting, troubleshooting, and communicating information about your power systems. To meet these requirements, TEST LEADS can conduct a comprehensive site survey that is essential to develop or to update existing single-line diagrams or complete electrical system drawings.

Short Circuit Co-ordination and Studies

The Petroleum and Chemical Industry recommend that Arc Flash calculations be completed in conjunction with short circuit calculations and protective device coordination to achieve the most accurate Arc Flash Hazard results. Short circuit and coordination studies verify protective devices and arc hazard ratings, calculate momentary interrupting and relay currents, establish settings for all types of protective devices, and coordinate your entire power distribution system to minimize downtime. TESTLEADS specializes in conducting these studies that provide vital information you need to ensure compliance with OSHA requirements.

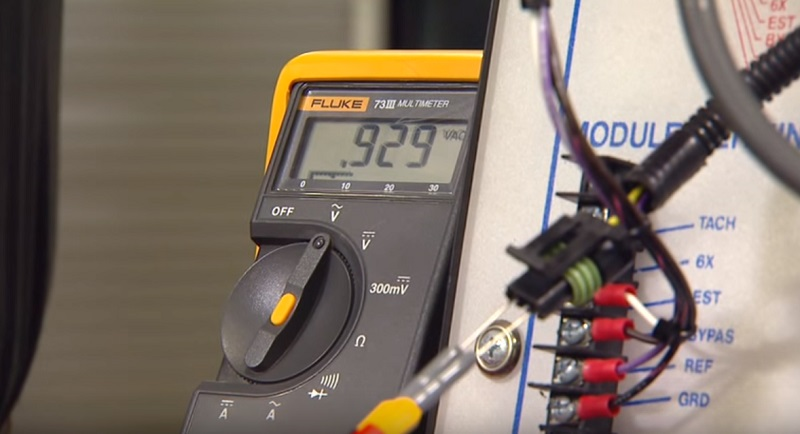

Electrical System Acceptance Testing and Services

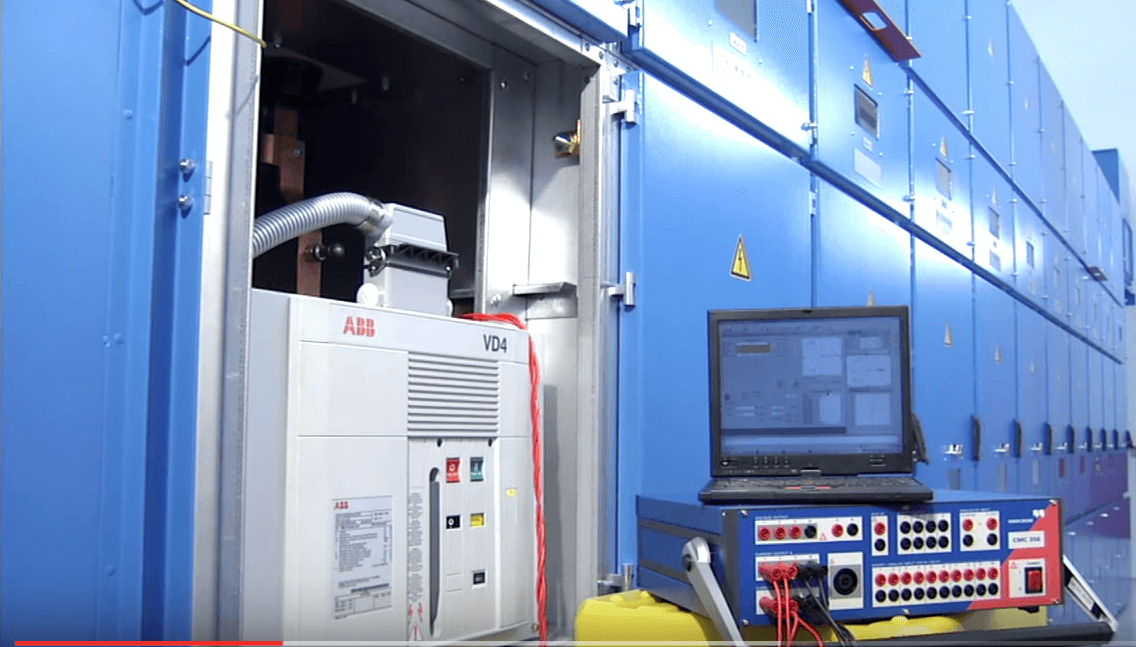

Acceptance testing and testing services provide customers with the assurance that their equipment complies with the qualifications and establishes a base line for future reference. Skilled engineers and technicians utilizing the latest state-of-the-art test equipment can assure our customers a timely testing for their plants.

LV, HV Switchgear

- Contact Resistance measurement for Circuit breaker and Busbar

- Primary injection test for Current and Potential Transformers

- CB Timing test

- Protection relay calibration and testing

- Insulation resistance test

- High voltage withstand test

- Functional test of components & Interlock and control system checks

Transformers

- Turns ratio and Vector group test

- DC Winding resistance measurement

- Oil dielectric strength test (BDV)

- Oil dissolved gas analysis (DGA)

- Insulation resistance/ Polarization index measurement

- High voltage withstand test

- Dielectric capacitance & Tan Delta measurement

Generator & Motors

- Insulation resistance/ Polarization index measurement

- DC Winding resistance measurement

- High voltage withstand test

- Dielectric capacitance & Tan Delta measurement

Cables & Bus duct

- Insulation resistance test

- DC High voltage withstand test for cables

- Contact Resistance measurement for Bus duct

- High voltage withstand test for bus duct

LPS & Grounding system tests

SF6 - Dew point analyser Test

Infrared Thermography (IR)

Online Partial Discharge Test (OLPD)

Transformer Oil Purification & Repair Works

HT Cable ID / spiking & splicing job / cable termination works

Preventive & Predictive Maintenance Services

TEST LEADS is taking a new look at preventive and predictive maintenance by combining well-established engineering principles with cost-effective programs and technology that make maintenance manageable throughout your facility. TEST LEADS preventative maintenance programs provide our customers with the peace of mind that their power system is functioning properly, safely, and reliably. Our structured programs are custom designed to work with any type or size of system. Our testing services address the challenge of substation reliability, with proper testing and calibration of the protective devices, the likelihood of nuisance tripping and damage to substation equipment and personnel is reduced drastically. TEST LEADS designs programs that work with our customer's budgetary and operational needs. Our programs will ensure that any applicable regulatory and reliability compliance requirements are fulfilled.

- Custom Preventive Maintenance

- Monthly Inspection of Substations

- Transformer Inspections

- Annual Testing of Electrical Equipment

- Substation Inspections & Maintenance

- Scheduled Outage Services

Preventive Maintenance Services

A properly maintained electrical system will function correctly and its protective features will minimize equipment damage when called upon to perform. Fewer equipment failures will keep operational costs to a minimum and can extend the life of the system as a whole.

Key service offerings

- Transformer testing (power factor, turns ratio (TTR), winding resistance)

- Sf6 gas analysis and leak detection

- Insulating oil analysis

- Switchgear and bus duct testing

- Protective relay testing & calibration (electro-mechanical, solid state, microprocessor)

- Meter calibration

- Power system studies

- Motor & Generator testing

- CB breaker testing

- Low voltage & medium voltage breaker testing

- Thermo graphic surveys

- Station battery system testing

- Earth/ground testing

- Power cable testing and

- Partial Discharge testing

Predictive Maintenance Services

Test leads in-service inspection and testing program provides comprehensive predictive services for obtaining and testing liquid samples, infrared inspections, partial discharge & corona detection, and visual inspections of entire substations or distribution systems and equipment. We maintain an inventory of state-of-the-art predictive maintenance equipment. Under our program, we provide comprehensive engineering reports detailing and summarizing the deficiencies discovered and make recommendations for repairs. Inspections, testing, and maintenance are performed by Test Technicians with Professional Thermography training. Information collected is reviewed and appraised by engineers experienced in electrical apparatus testing and maintenance practice.